Geomembranes are extruded from high density polyethylene (HDPE) of a predetermined and specially selected mass per unit area within the range of 400-850 g/m2, and optimal height and diameter of dimples. The VENTFOL geomembranes are modern components of a moisture protection system for buildings and structures of civil engineering, road and water engineering. Their simple installation allows you to make really large, waterproof vertical and horizontal surfaces.

The particular design of geomembranes manufactured by Plast-Master consists in a mutually perpendicular arrangement of dimples, called an orthogonal system. It provides maximizing the water flow in the plane of the product, facilitates installation within the area of plane bends, increases the tensile strength, especially within the fabrication direction, compared to the diagonal system. It gives the opportunity to make a so-called, modular seam.

A wide range of VENTFOL products was developed specifically to meet the specific and diverse requirements of our customers and comprises the following types:

![]() – this geomembrane traditionally proved its worth for a moisture barrier systems both in residential as well as industrial buildings, adapted to moderate soil conditions, and moderate loads, appreciated for its ease of installation.

– this geomembrane traditionally proved its worth for a moisture barrier systems both in residential as well as industrial buildings, adapted to moderate soil conditions, and moderate loads, appreciated for its ease of installation.

![]() – a membrane with increased weight per square meter and optimally selected mechanical strength, tested under conditions of elevated risk of mechanical damages and challenging ground conditions.

– a membrane with increased weight per square meter and optimally selected mechanical strength, tested under conditions of elevated risk of mechanical damages and challenging ground conditions.

![]() – a geomembrane designed to withstand high mechanical loads. Designed for building insulation especially in civil engineering, for example watertight road drainage ditches.

– a geomembrane designed to withstand high mechanical loads. Designed for building insulation especially in civil engineering, for example watertight road drainage ditches.

![]() – a geomembrane designed for high mechanical loads (pressure, tearing, stretching), soils containing sharp edge rock material, especially suited for deep underground garages, loaded bridge abutments and all kinds of civil engineering, for example tunnels, bridges, culverts.

– a geomembrane designed for high mechanical loads (pressure, tearing, stretching), soils containing sharp edge rock material, especially suited for deep underground garages, loaded bridge abutments and all kinds of civil engineering, for example tunnels, bridges, culverts.

![]() – a geomembrane included in the group with the highest weight per square meter, adapted to extremely difficult conditions both in terms of loads as well as soil conditions, especially popular for individual projects, for example road and tunnel construction, railway applications.

– a geomembrane included in the group with the highest weight per square meter, adapted to extremely difficult conditions both in terms of loads as well as soil conditions, especially popular for individual projects, for example road and tunnel construction, railway applications.

GEOMEMBRANY – VENTFOL – Super – Strong – Extra – Power – geomembranes with improved mechanical properties, compressive strength, tear resistance and tensile strength, give the opportunity to create your own watertight barriers after using a butyl tape for sealing membrane sheet joints of and places of membrane punctures.

Legend:

MD – properties in the machine direction; CMD – properties in the cross machine direction.

The table contains average values of each property from tests made in our company during the period from September 2013 until March 2014. Declared values are included in the Declarations of Performance available in the “Downloads” tab. The above data is given with the best of our knowledge, test results, experience and in good faith, but in practice, the differences in materials, methods of product usage, and site conditions, which are beyond our control, may affect the need for verification. Characteristics of a product specified in the data, written recommendations, and other guidelines provided cannot be grounds to assume PLAST MASTER’s responsibility. It is not our intention to violate any patents or licenses. The current declarations of performance are available on our website.

Applications of VENTFOL Geomembran

A wide range of masses per unit area and carefully selected raw materials make that our VENTFOL geomembranes are widely used in construction. Starting from single-family dwellings and outbuildings, located on light, permeable soils and ending with multi-family buildings, industrial and civil engineering buildings, situated in difficult ground conditions. For applications in residential construction we suggest, lightweight and durable VENTFOL STANDARD geomembrane. It is an attractive value for money product.

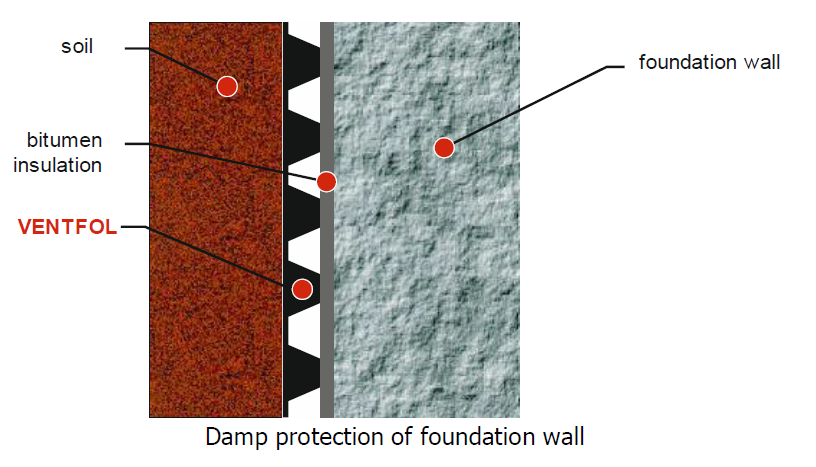

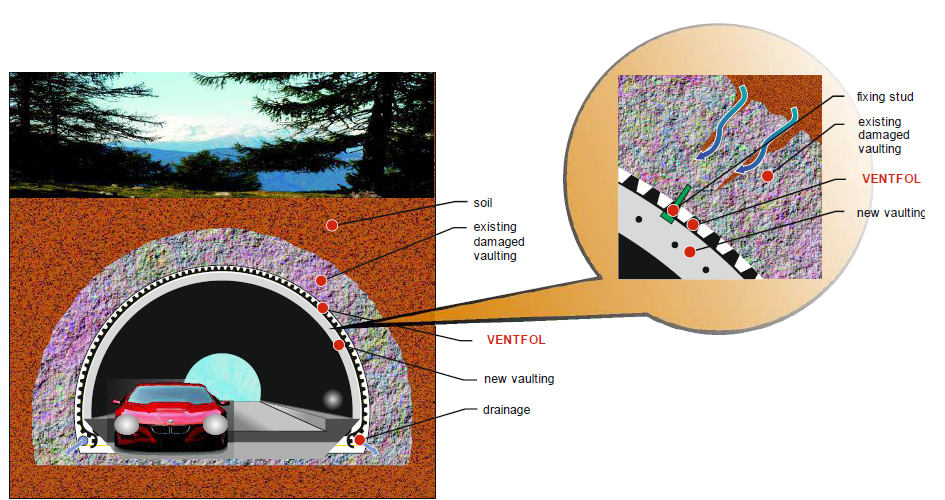

VENTFOL Geomembranes with a weight of 500 g/m2 and higher (Super, Strong, Extra, Power) are perfectly suited for areas requiring high compressive strength, impact resistance and surface pressures, for example, deep multi-storey basements, garages, abutments of bridges, tunnel linings, for individual projects of dewatering and drainage systems, roads, bridges, railway embankments. Geomembranes eliminate the possibility of mechanical damages of the outer insulating bitumen layer of foundations and engineering structures during backfilling and protects the insulation during subsidence.

Application of VENTFOL geomembranes for the renovation of damaged vaulting of existing tunnels:

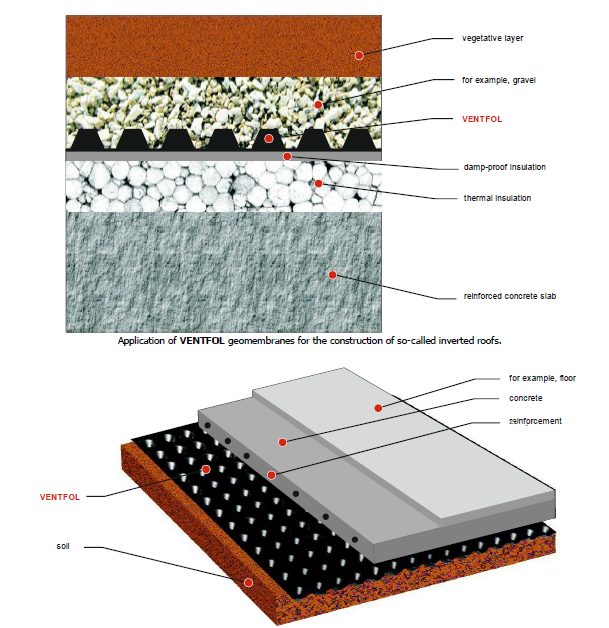

VENTFOL geomembranes, in addition to the conventional usage for protecting foundations, have a wide application for structural elements of the so-called inverted roofs, “Green roofs”, ceilings, terraces, flat roofs and floors.

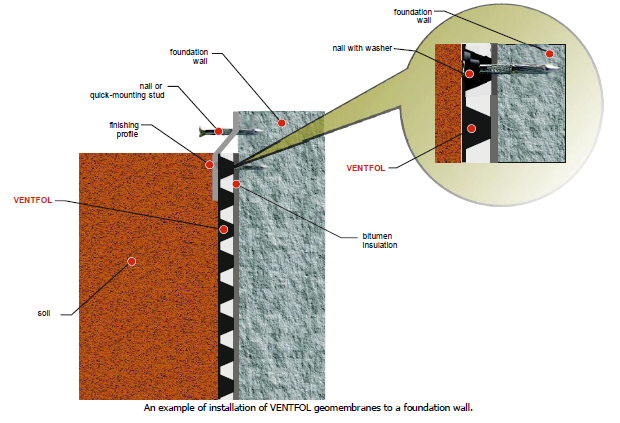

Installation Method

Membrane sheets shall be fixed with steel nails or studs at the spacing of approx. 60 cm. When fastening to polystyrene foam, you can use quick mounting studs. While joining membrane sheets, you shall make a so-called seam – an overlap of approx. 30 cm width. With horizontal installation of membranes, when overlapping large areas, it is good to use double-sided adhesive tape. To obtain a tight seal joint of bands, make a sealed modular seam. In order to do this, place one or two paths of butyl tape within the overlap area.

When using our membranes, you shall always follow the detailed recommendations set out in the technical design of an object. Membranes may be installed in any weather conditions.

An example of installation of VENTFOL geomembranes to a foundation wall:

Transport and Storage

Membranes are supplied in rolls on transport pallets protected. During the transportation and storage, membranes shall be protected against mechanical damages and high temperatures, for example, during welding works.

Geomembran Accessories:

Documents to download

Technical Specification And Declaration of Properties:

In order to obtain a document for a previous version, please contact us at the following address: biuro@plastmaster.pl