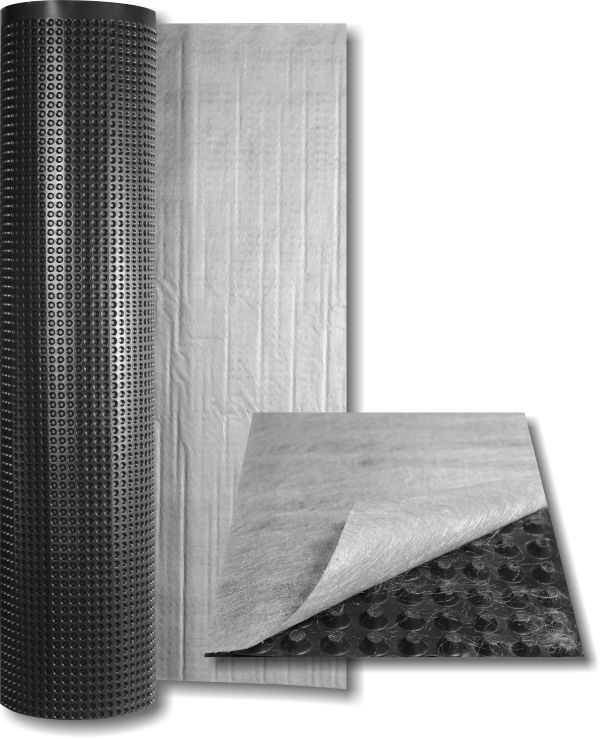

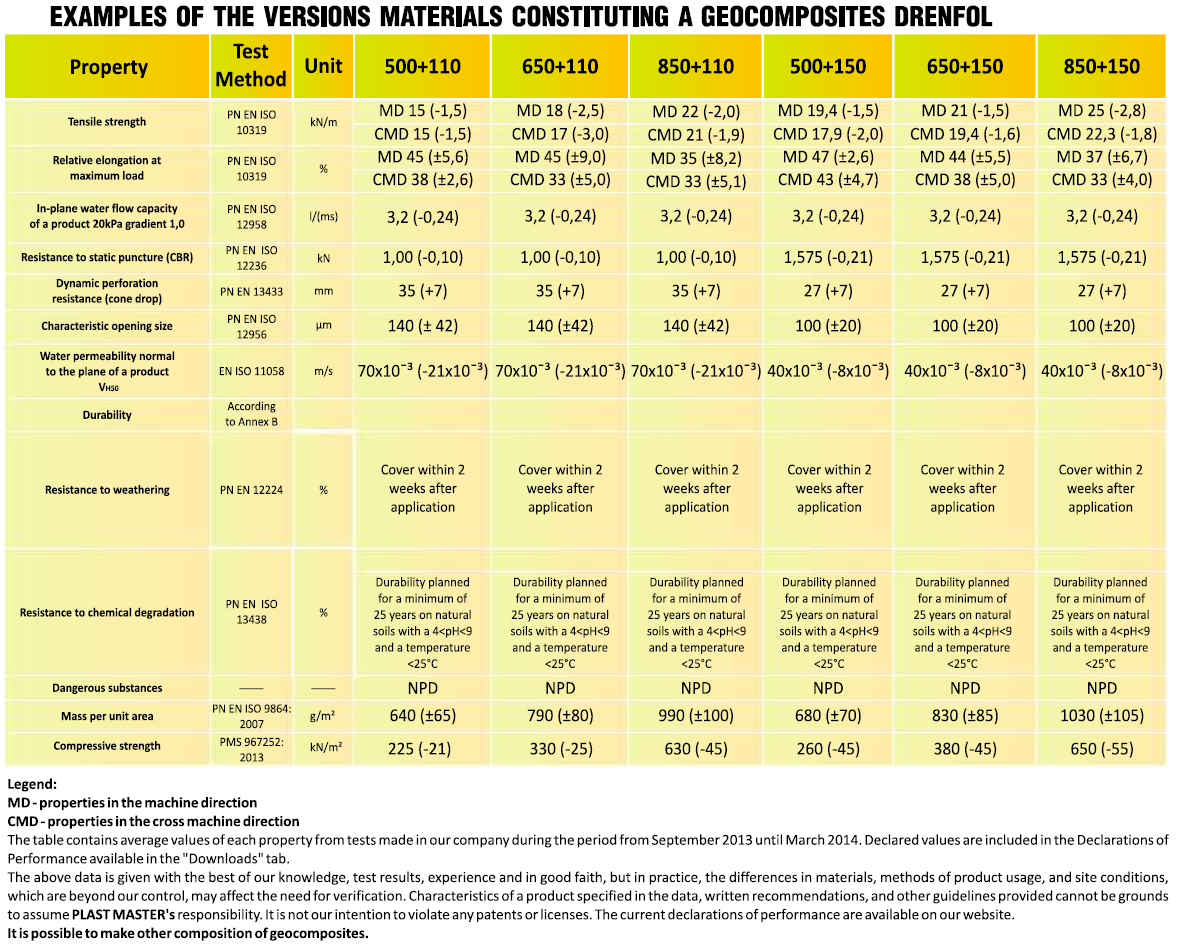

Our DRENFOL geocomposites were developed by a combination of dimpled HDPE geomembrane of a mass per unit area within the range of 500 to 850 g/m2 with a special geotextile made of PP fibers of a mass per unit area within the range of 90‑150 g/m2. Geocomposites are characterized by a very high tensile strength and compressive strength.

Combination of geocomposite components is carried out by means of hot-melt (non-drying) adhesive, which provides durability of connection at operating conditions, while ensuring disconnection of layers at the stage of installation and re-bonding after installation of, for example, a drainage pipe. This provides protection, within the area of joining strips, against the penetration of soil particles into flow channels, protecting the geocomposite from clogging (silting). This technology is especially important when connecting together multiple membrane sheets, giving the possibility to make a sealed seam of HDPE geomembrane sheets especially when using a butyl tape (modular sealed seam) for the installation. Developed orthogonal system of membrane dimples results in maximizing the flow velocity of water or liquids drained.

DRENFOL geocomposites are modern elements of contemporary moisture and damp protection systems through simultaneous implementation of filtration, separation and drainage functions (F + S + D).

Apllication od DRENFOL Geocomposites

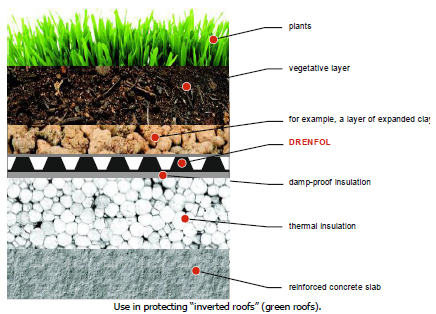

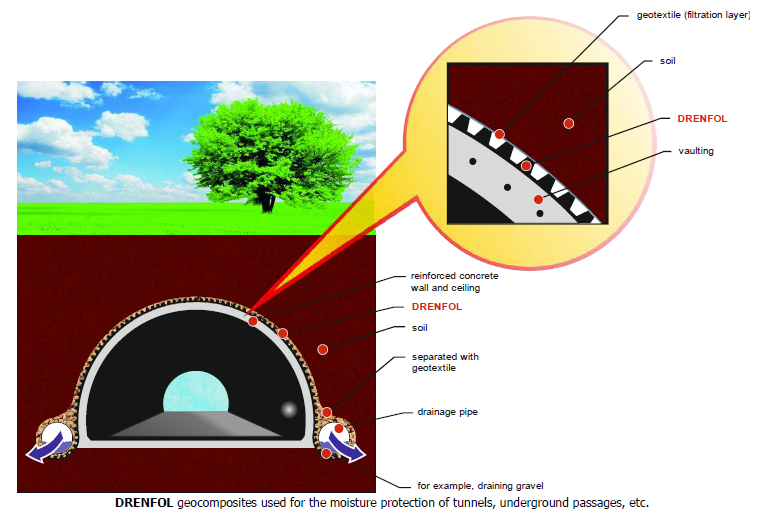

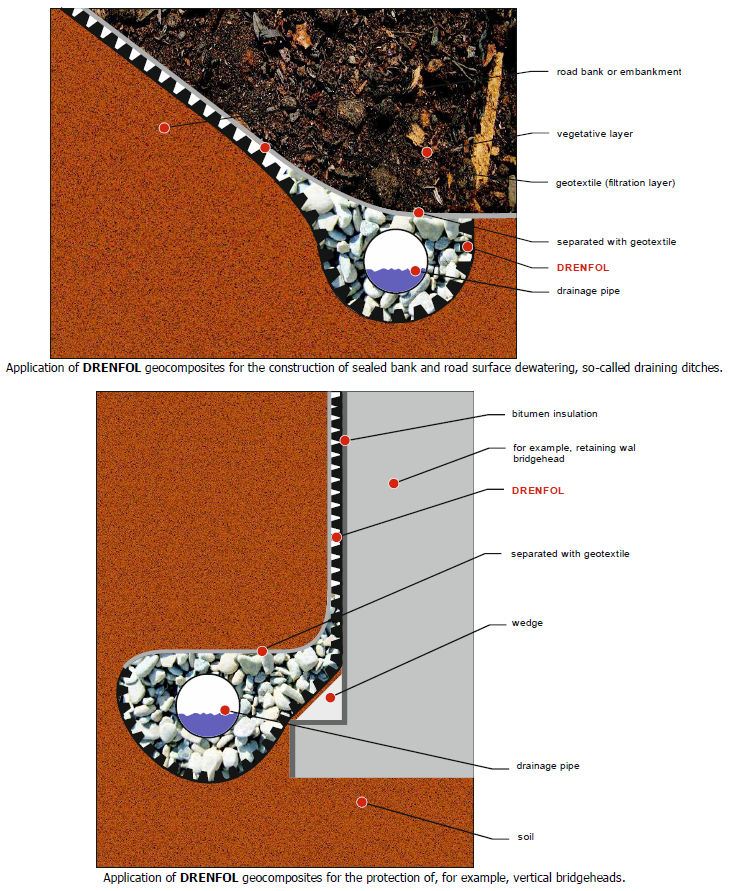

Due to their mechanical properties, separation, drainage and a wide range of filtration capabilities, DRENFOL geocomposites are an appreciated solution used for moisture protection systems, and as a protecting element of inverted roof installations, so-called green roofs, both in residential and industrial buildings. At the same time, through a high tensile strength and compressive strength properties, the DRENFOL geocomposites are suited for civil engineering structures especially in road and railway construction for drainage systems of roads, embankments, bridge abutments, culverts and tunnels, and for rainwater drainage systems of roadside retention tanks. The DRENFOL geocomposites are also widely used in the construction of rainwater drainage systems of landfill tops.

Installation Method

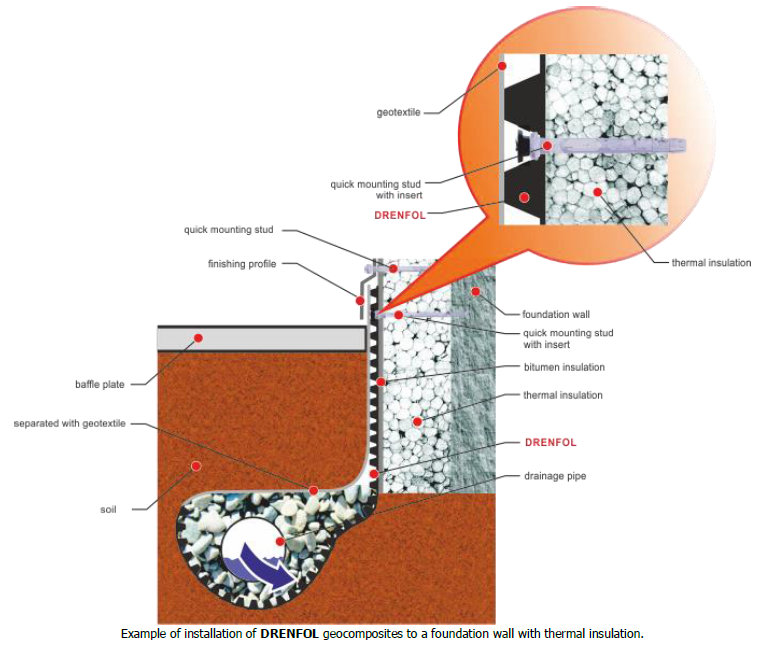

DRENFOL geocomposite shall be laid with the geotextile toward the soil in case of fastening to any kind of vertical partitions walls. Fix them using steel nails or studs at a spacing of about 60 cm. While joining geocomposite strips, you shall make a so-called modular seam – an overlap of approx. 20 cm width by unsticking the geotextile from one of sheets. Make the joint and re-apply the unsticked piece of the geotextile. Membrane joints and possible punctures shall be sealed with butyl tape. With horizontal installation, the geocomposites shall be laid in the direction of the planned water inflow (outside of the protected area). When laying the geocomposite in a horizontal position, always remember to keep a minimum 2% drop of the prepared substrate in the direction of the water receiving system (the detail inclination is defined by a technical design). Any punctures or damages of HDPE membrane occurred during installation shall be sealed with butyl tape. To obtain a tight seal joint of bands, make a sealed modular seam. In order to do this, place one or two paths of butyl tape within the overlap area. When using our membranes, you shall always follow the detailed recommendations set out in the technical design of an object. Membranes may be installed in any weather conditions.

Transport and Storage

Membranes are supplied in rolls on transport pallets protected. During the transportation and storage, membranes shall be protected against mechanical damages and high temperatures.

Technical parameters of Drenfol

Documents to download

In order to obtain a document for a previous version, please contact us at the following address: biuro@plastmaster.pl